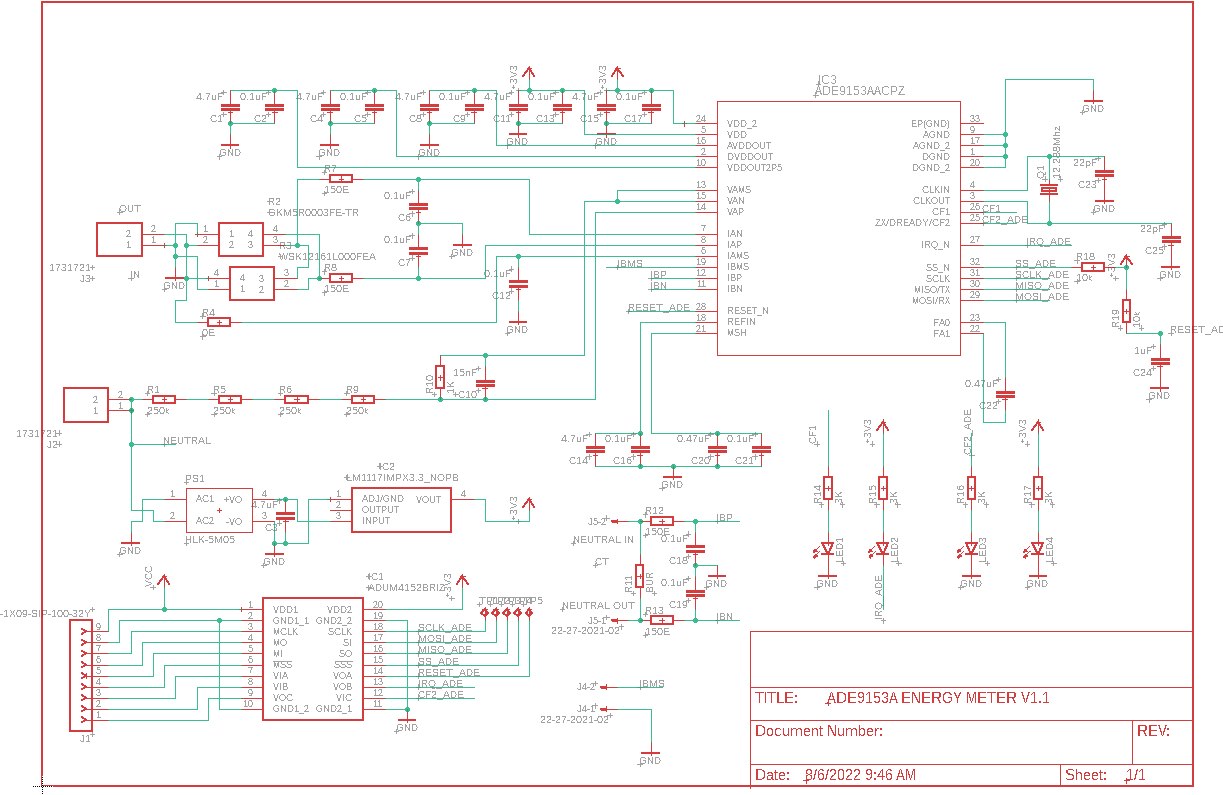

Based on the analysis of the schematic titled ADE9153A ENERGY METER V1.1, here is an updated and detailed version of the blog post, incorporating specifics from the actual circuit design:

Designing a Custom ADE9153A Energy Meter Evaluation Board – Schematic and PCB Overview

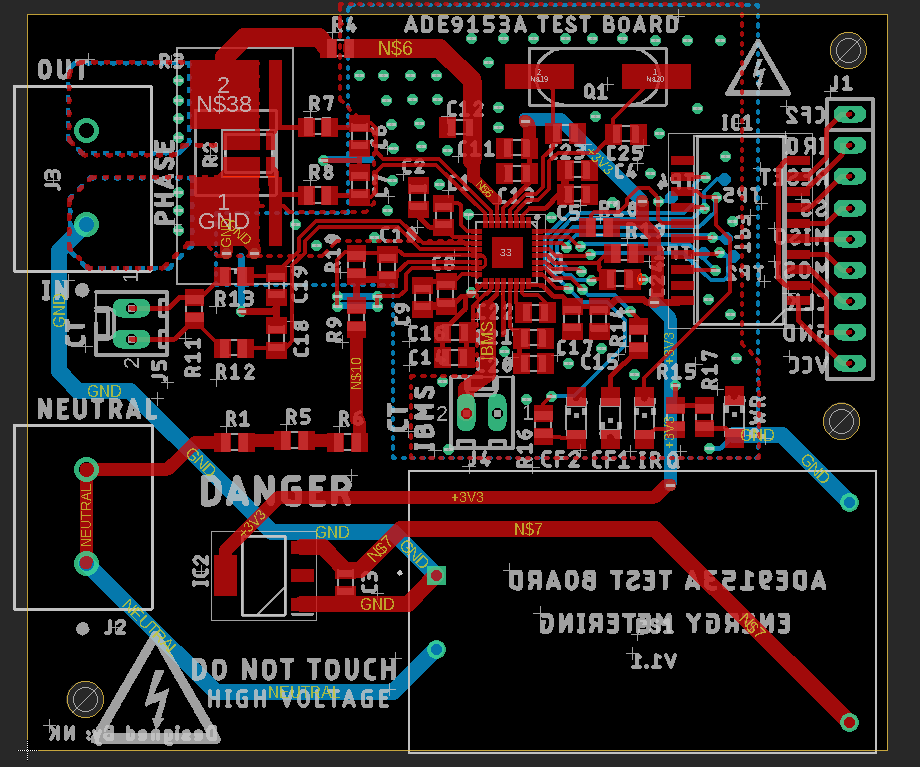

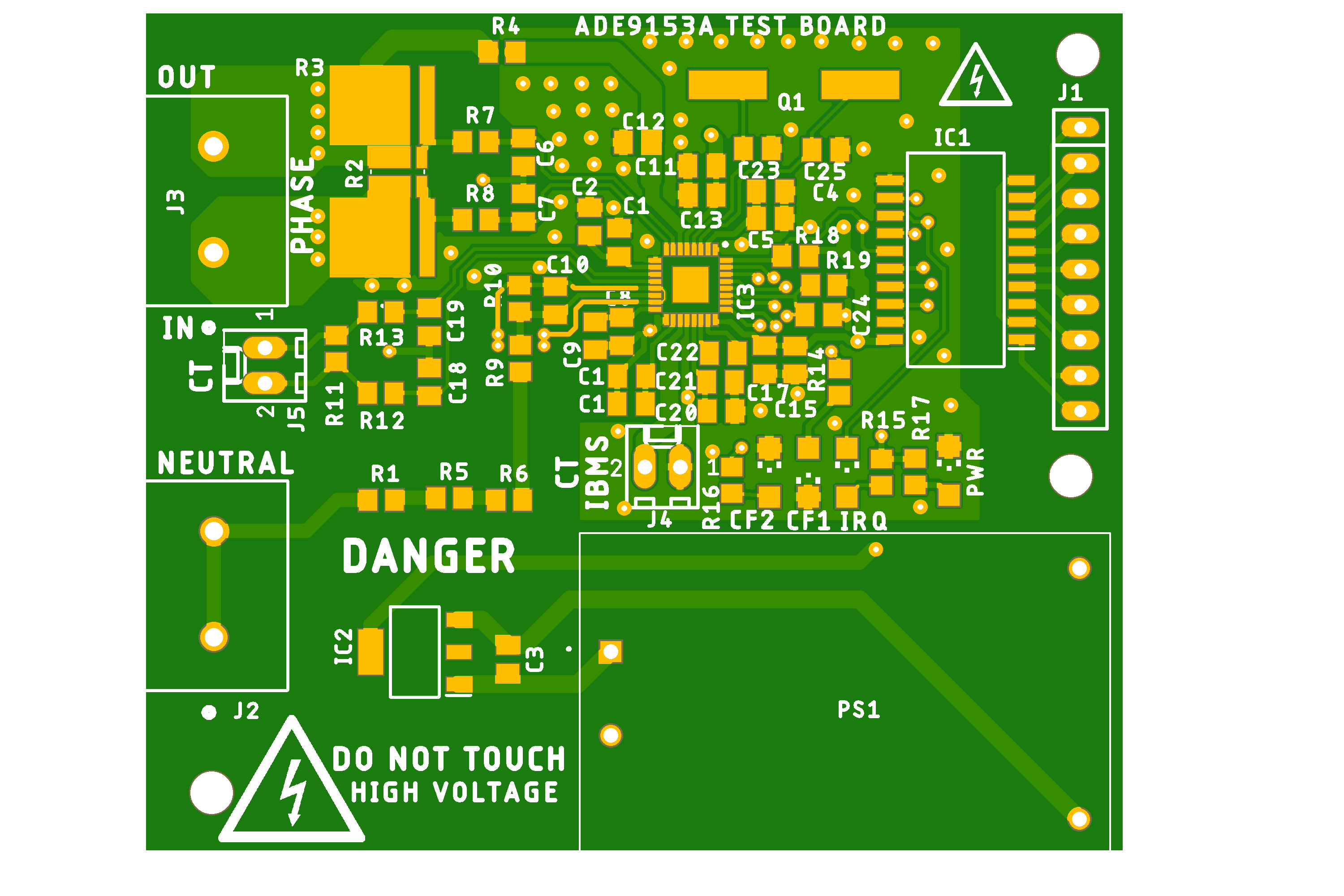

This article provides a technical walkthrough of a custom-designed energy meter evaluation board using Analog Devices’ ADE9153A IC. The schematic and PCB were developed in Autodesk Eagle, with the goal of creating a compact, accurate, and safe platform suitable for evaluating single-phase energy measurement systems.

IC Selection – ADE9153A

The ADE9153AACPZ serves as the core of the design. It supports accurate measurements of active, reactive, and apparent power, voltage, current, power factor, and line frequency. Integrated mSure® autocalibration ensures long-term accuracy without external calibration.

Key Sections of the Schematic

1. Voltage and Current Sensing

-

Voltage Sensing:

- Voltage is tapped from the AC input via a resistor divider using four high-value 250kΩ resistors in series.

- Additional RC filtering ensures signal stability before entering the ADE9153A’s voltage sensing pin (

VAP,VAN). - Safety and filtering are handled with multiple 0.1µF capacitors and 15nF ceramic caps.

-

Current Sensing:

- The design uses a WSK12161L000FEA precision shunt resistor.

- Inputs

IAP,IANare connected directly to the ADE9153A for current channel A, with low-noise analog filtering in place.

2. Power Supply and Regulation

- AC-DC conversion is handled by a HLK-5M05 module, which steps down mains AC to 5V DC.

- A LM1117IMPX-3.3 LDO regulator further regulates the 5V down to 3.3V, required for the ADE9153A and logic components.

- Bypass capacitors (4.7µF, 0.1µF, 1µF) ensure clean power rails.

3. Digital Isolation and Interface

- An ADUM4152BRIZ digital isolator provides SPI isolation between the metering IC and the external microcontroller interface.

- The SPI lines (

MOSI,MISO,SCLK,SS_N) and interrupt signals (IRQ_N,CF1,CF2) are all routed through the isolator. - Adequate test points are provided for SPI lines and control signals.

4. Clock Circuit

- The system uses a 8.288 MHz crystal oscillator with 22pF load capacitors to feed the

CLKINpin of ADE9153A. - The

CLKOUTpin is available for further timing use or debugging.

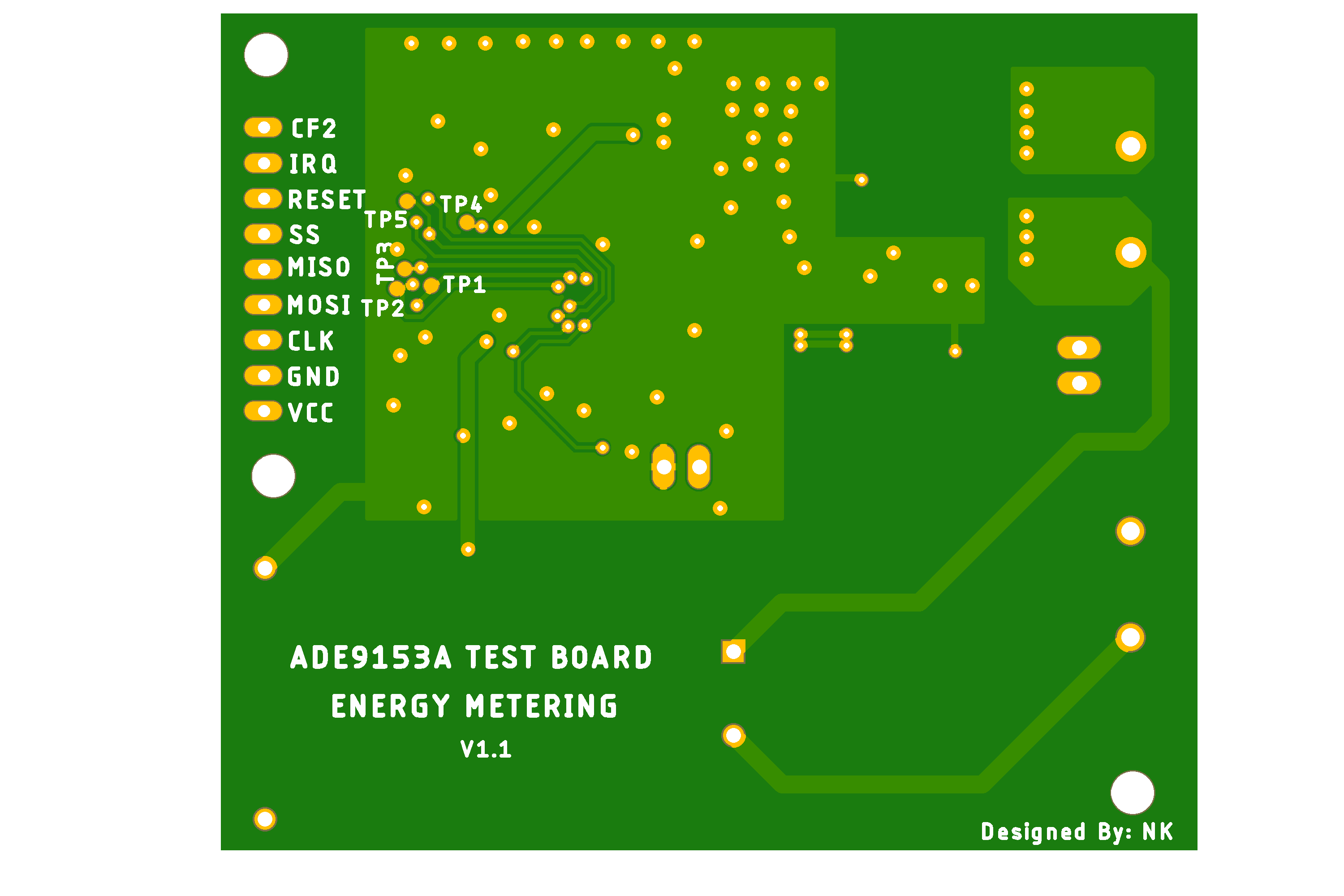

5. Headers and Debug Access

- J2, J3, J5 headers are provided for interfacing with an external MCU.

- Clearly labeled signals like

RESET_ADE,IRQ_ADE,MOSI_ADE,SCLK_ADEsimplify firmware development. - Test points (TP1–TP5) aid in probing key nodes during bring-up.

PCB

Safety and Layout Practices

- The schematic includes series 150Ω resistors and 0.1µF capacitors at several critical nodes to reduce high-frequency noise and protect against transients.

- High-voltage and low-voltage sides are physically isolated.

- Creepage and clearance are respected in PCB layout design to comply with safety norms for mains operation.

Referance

- Programming and Calibration details are here

- Evalution Board