Client

Designed and developed for Spring Technologies

Product Description

The NuLock is an IoT-based smart lock designed for petrol tanker vehicles in petrochemical industries. The system ensures that tanker outlet locks only open in specific authorized areas, such as refilling depots or unloading stations.

A key feature is its geo-fencing capability: the lock operates only in pre-defined zones set by the administrator. This prevents unauthorized fuel theft while the tanker is in transit.

The product is built to comply with intrinsic safety standards, as mandated by the Petroleum & Explosives Safety Organization (PESO), ensuring it can safely function in hazardous, explosion-prone environments.

NuLock is available in two variants:

- Key & Lock System

- Fixed Lock System

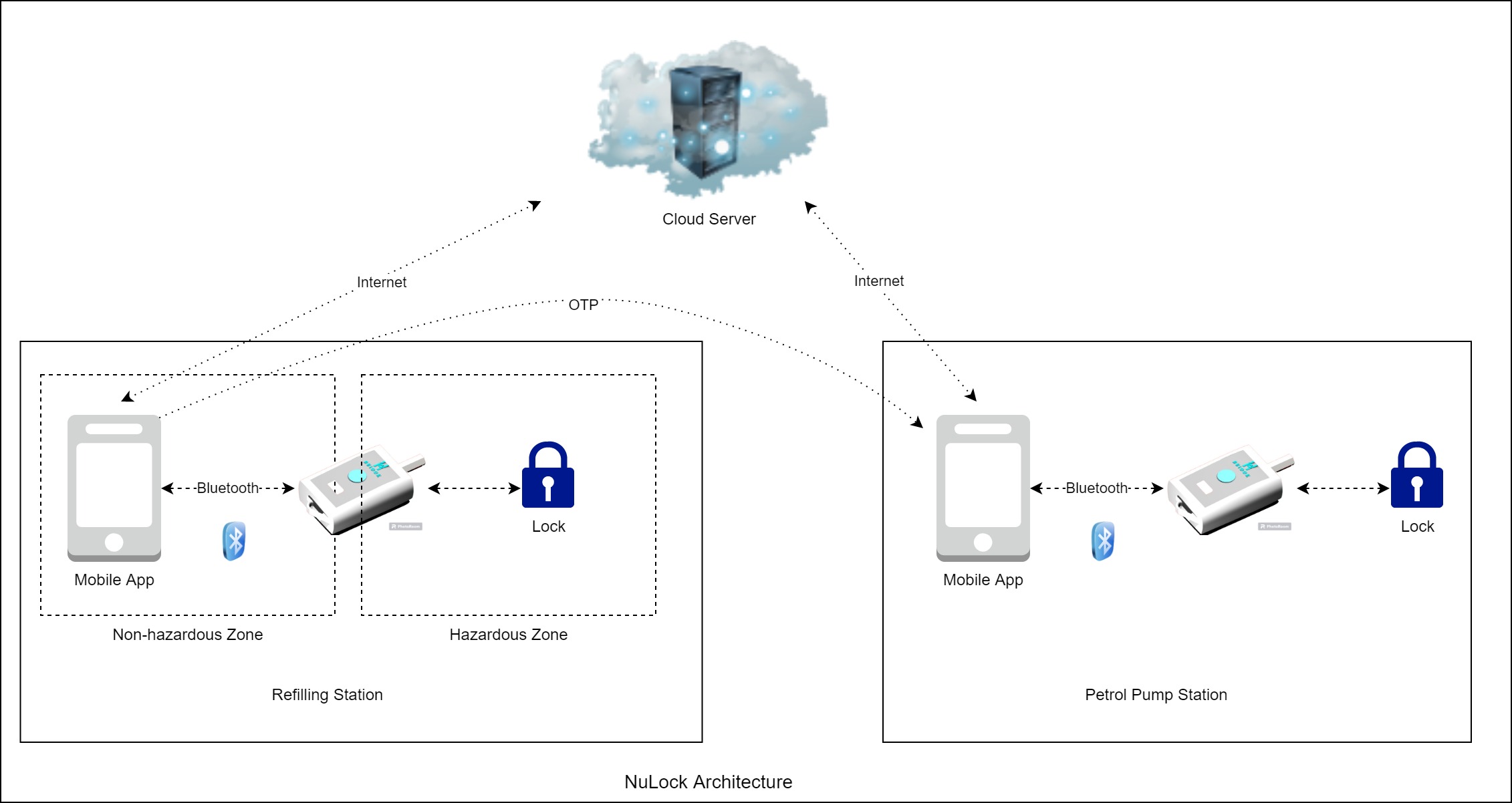

Working of Key & Lock System

This system comprises three main devices: Mobile App, Key, and Lock.

-

Task Creation

- The Android mobile app is used to create a task (access pass) for unlocking/locking.

- Each task includes parameters such as date, time slot, lock ID, access code, and area code.

- The admin creates a refilling task when the tanker arrives at the depot and an unloading task when it reaches the petrol pump station.

- The mobile app uses GPS signals to confirm the tanker’s location before assigning tasks.

- An OTP is generated for unloading operations.

-

Task Loading

- Once created, the task is transferred to the Key via Bluetooth connectivity.

- Since mobile phones are not allowed inside hazardous zones (due to explosion risks from signals), the operator only carries the Key into the restricted area.

-

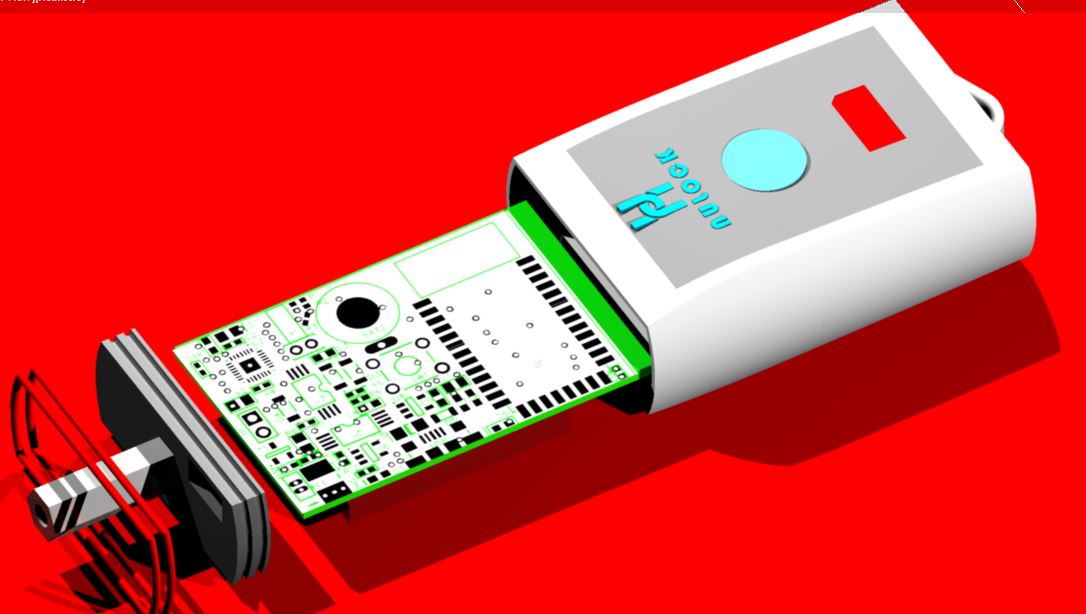

Intrinsic Safe Key

- The Key is designed and certified to work safely in hazardous zones.

- It incorporates safety features to prevent sparks/ignition.

- Powered by a small lead-acid battery, the Key also energizes the lock (the lock itself has no battery).

- Each lock has a unique lock ID, verified by the Key before opening.

- A single Key can operate multiple locks, provided tasks for each lock ID are preloaded.

-

Verification & Unlocking

- At the petrol pump, the operator enters the admin-generated OTP into the mobile app.

- The app verifies OTP validity, GPS location, and time slot.

- Upon successful verification, the task is loaded into the Key.

- The operator inserts the Key into the lock, which verifies parameters and unlocks.

-

Data & Logging

- A custom protocol transfers both power and data through only two wires between Key and Lock.

- Bluetooth BLE is used for mobile-to-Key communication.

- The Key stores logs (lock ID, timestamps, access events).

- When reconnected to the mobile app, logs are synced to the cloud server for audit and monitoring of unauthorized use.

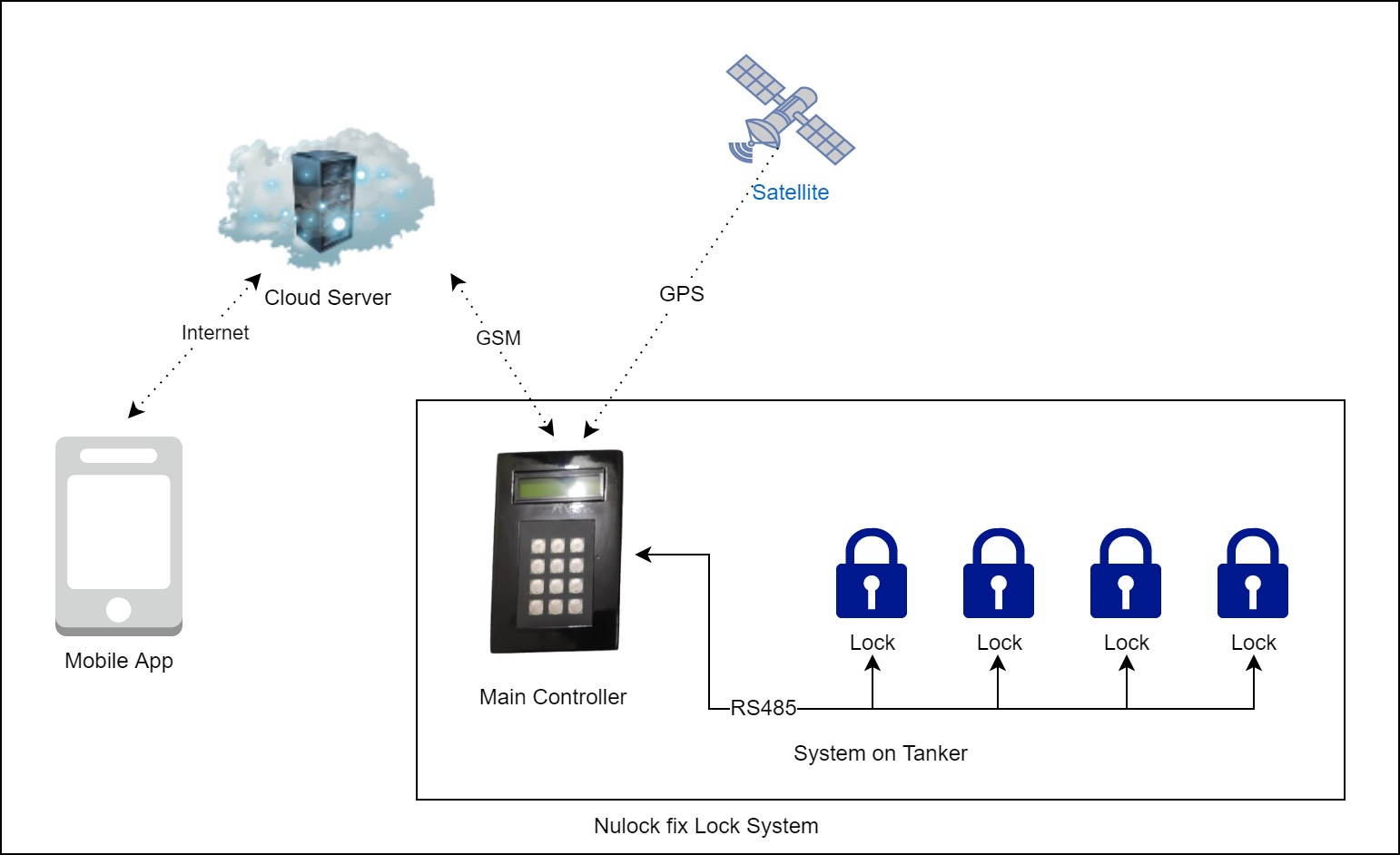

Working of Fixed Lock System

In this variant, the locks are permanently mounted on the tanker and operated through a main controller. No portable keys or mobile devices are required inside hazardous zones.

-

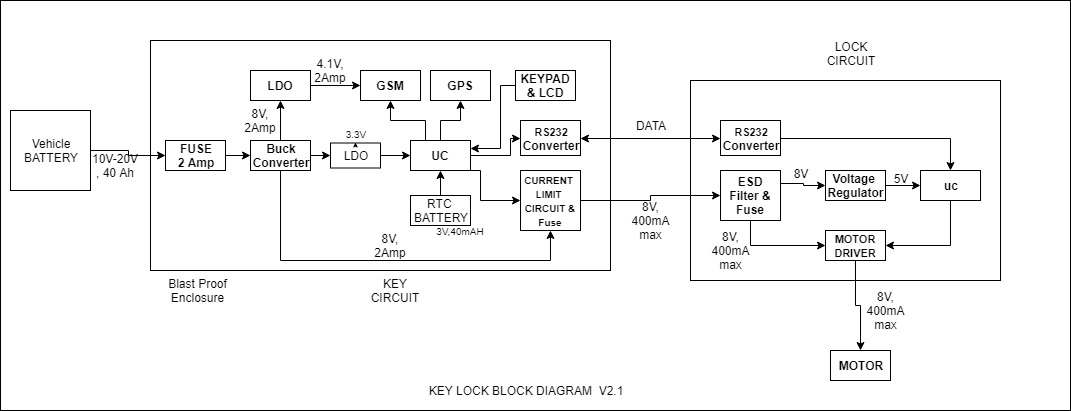

Main Controller Setup

- Installed inside a blast-proof enclosure within the tanker.

- Equipped with GPS (for location tracking) and GSM (for server communication).

- Connected to the locks via wired communication.

-

Task Creation & Synchronization

- Admin creates tasks and OTPs via the mobile app (similar process as the Key system).

- Tasks are synchronized directly with the main controller through the internet.

-

Operation

- The controller has an LCD display and keypad for operators to enter OTPs and check system status.

- One controller can manage multiple outlet locks installed on tanker valves.

-

Safety Compliance

- Both controller and locks are designed to meet intrinsic safety standards, preventing ignition risks in hazardous petrochemical environments.

Advantages of Fixed System:

- Eliminates the need for carrying portable keys.

- Centralized control for multiple outlet locks.

- Real-time connectivity with server via GSM.

- Enhanced security through GPS-enabled geo-fencing and OTP validation.

Technical Highlights

- Geo-fencing support – Lock operates only in authorized areas.

- PESO-compliant Intrinsic Safety Design – Prevents sparks or ignition.

- Multiple Connectivity Options – GSM, GPS, RS485, Bluetooth BLE.

- Task & OTP Based Access – Date/time/location-based secure unlocking.

- Audit Trail – Logs stored in memory and synced to cloud.

- Multiple Variants – Key & Lock System for portable access; Fixed Lock System for integrated tanker control.

- Blast-Proof Enclosure – Ensures safe housing of electronics in tanker systems.

Benefits & Applications

- Prevents fuel theft during tanker transportation.

- Ensures compliance with safety standards in explosive-prone petrochemical environments.

- Provides remote monitoring and cloud-based audit trail of lock activities.

- Simplifies operations at refilling and unloading stations with automated geo-fenced and OTP-controlled access.

- Scalable to manage multiple locks per tanker.

Main Controller

Lock Installed on Petrol Tanker

Demo of Key Lock Model

Demo of Fixed Lock Model