📌 Introduction

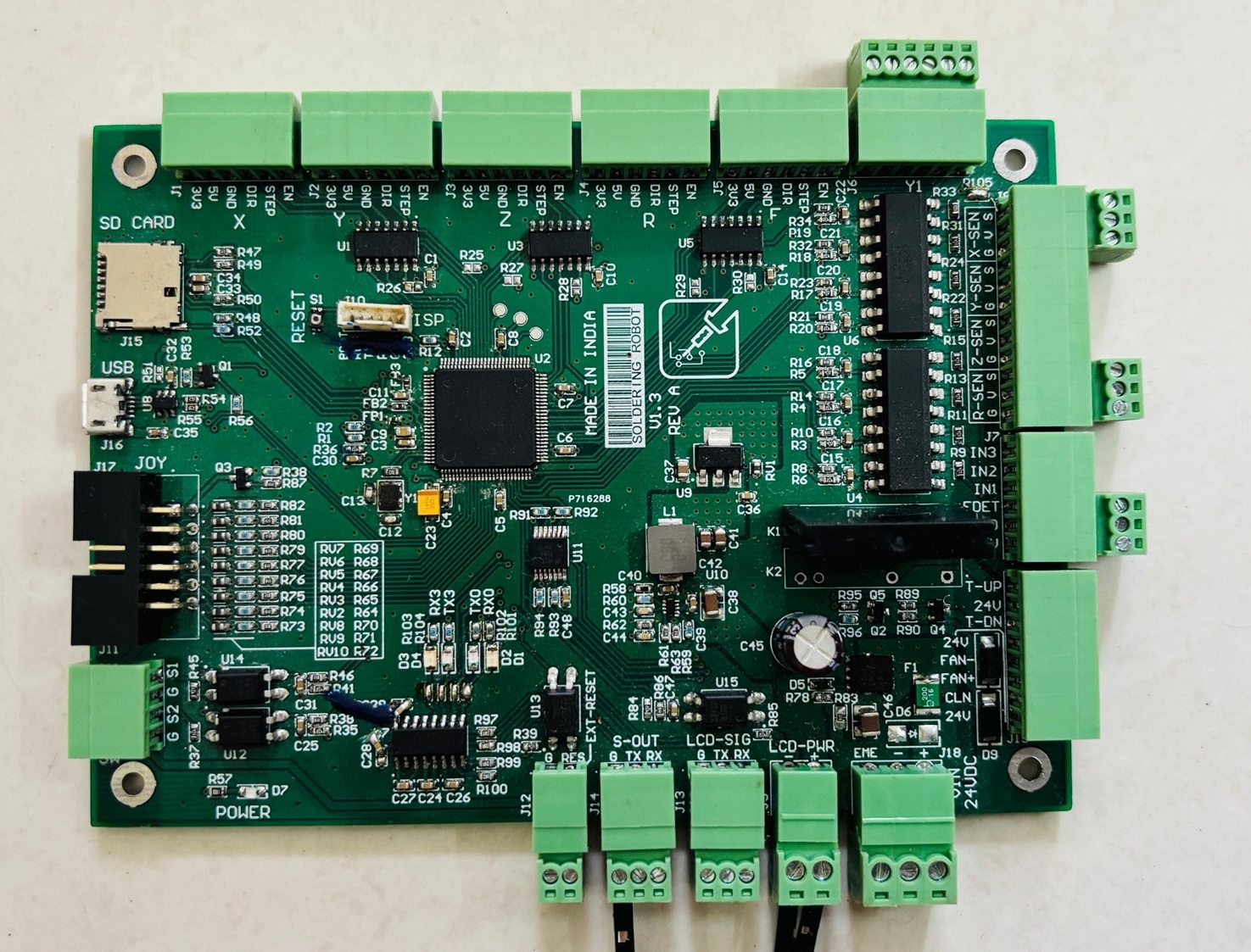

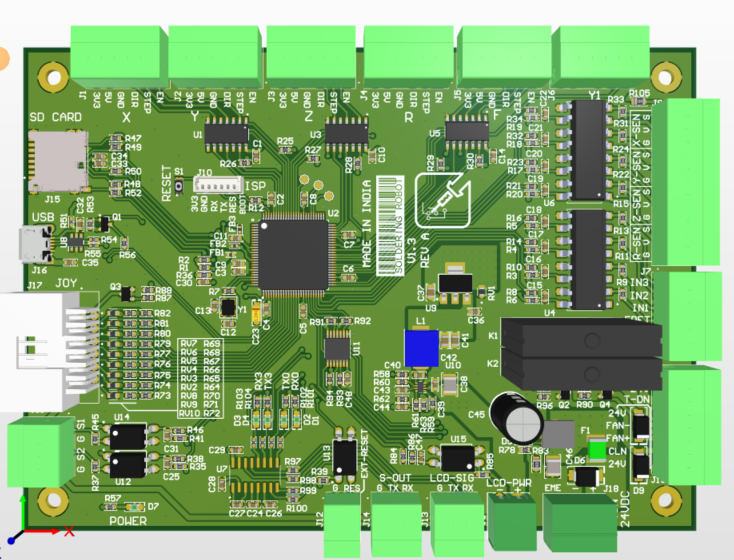

This custom-designed control board is developed to support CNC machines, 3D printers, and robotic platforms that require real-time, multi-axis motion control. Inspired by the SKR V1.4 board, it combines motion control, power management, sensor interfaces, and connectivity into a compact and reliable unit.

This board is currently integrated into our automatic soldering robot, where it manages coordinated movement, wire feed, and actuator control with high precision.

The design uses a 4-layer PCB layout to ensure signal integrity, heat dissipation, and power stability, which are critical for consistent performance in high-speed motion control systems.

💡 Purpose and Benefits

Generic controller boards often lack the modularity, safety features, and communication flexibility required in advanced or customized systems. This board was developed in-house to provide:

- Precise and synchronized multi-axis stepper control

- High current support with robust protection features

- Seamless integration with sensors and actuators

- Versatile communication through USB, UART, and Wi-Fi

- Compatibility with multiple open-source firmware platforms

Whether used in a 3D printer, CNC router, or custom robotic platform, this board offers reliable motion control and expandability for various applications.

🔧 Core Features

1. Power Management and Protection

- Accepts 24V DC input through high-current screw terminals

- Reverse polarity protection on input supply

- Fuse protection to prevent overcurrent faults on driver rails

- Onboard buck converters to generate isolated 5V and 3.3V logic voltages

- Optimized power routing with dedicated internal power planes

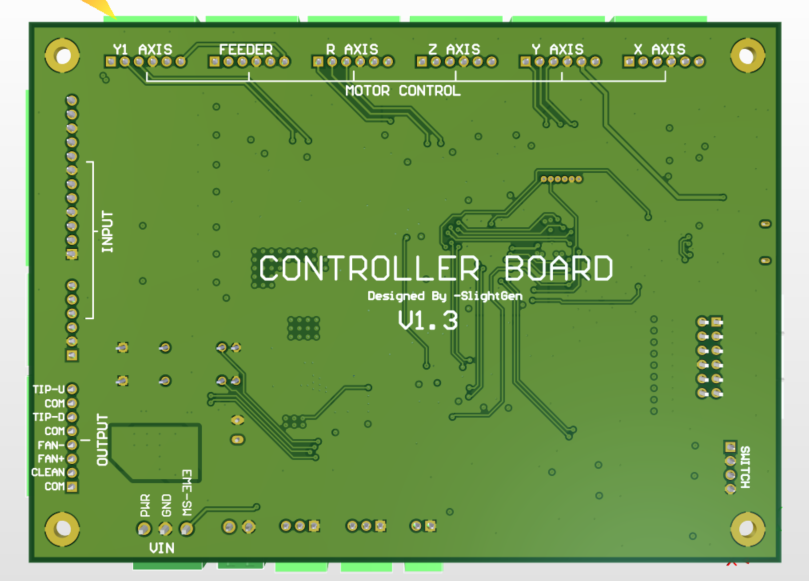

2. LPC1768 Motion Controller

- 32-bit ARM Cortex-M3 microcontroller running at 100 MHz

- Handles 4-axis motion control (X, Y, Z, R)

- Generates high-resolution step signals for external drivers

- Supports standard driver interfaces such as DRV8825, A4988, and TMC series

3. Onboard DRV8825 Stepper Driver

- Integrated stepper driver for direct motor control

- Supports microstepping and current regulation

- Useful for testing or operating a single axis without external modules

4. Sensor and High-Power Control Interface

- Multiple input ports for endstops, runout detection, or leveling sensors

- MOSFET-controlled outputs for fans, solenoids, soldering tools, or relays

- Inputs and outputs are firmware configurable and hardware isolated

5. ESP32-Based Expansion

- Provides additional GPIO capability and handles I/O tasks independently

- Adds Wi-Fi functionality for wireless communication and OTA updates

- Useful for remote control, diagnostics, or external HMI interfaces

6. Communication and I/O Ports

- USB interface for firmware flashing and host communication

- Multiple UART ports for toolheads, displays, or debugging

- General-purpose GPIO headers to connect switches, joysticks, or sensors

7. SD Card Interface

- Built-in microSD card slot for loading G-code files, configuration files, or firmware

- Enables offline printing or machine operation without a computer

- Useful for storing logs, diagnostic data, or program scripts in production use

💻 Firmware Compatibility

This board supports a range of open-source firmware platforms, allowing customization for various applications:

Marlin 2.0

Widely adopted in 3D printing, Marlin offers configurable motion control, thermal management, and support for multiple kinematic setups. It runs efficiently on the LPC1768 architecture and supports external drivers, sensors, and advanced features.

Smoothieware

A modular and streamlined firmware ideal for CNC applications. It provides smooth acceleration, high-speed step generation, and real-time G-code streaming. Suitable for machines requiring deterministic motion profiles.

Custom or Bare-Metal Firmware

The board is suitable for developers building custom robotics or automation firmware. It supports FreeRTOS or bare-metal development with direct register access and can be tailored for proprietary protocols and control logic.

🧠 Engineering Notes on 4-Layer PCB Design

The four-layer PCB layout enhances electrical performance by:

- Improving signal integrity for stepper and communication lines

- Reducing EMI and crosstalk via ground and power plane separation

- Providing better thermal performance for drivers and power switches

- Allowing compact and reliable routing for high-density components

🤖 Real-World Application: Soldering Robot

This controller is actively used in our automatic soldering robot, where it performs the following tasks:

- Controls four-axis coordinated motion (X, Y, Z, and rotating toolhead)

- Control High power Stepper motor driver.

- Drives solder wire feed using motor control and runout detection

- Controls pnematics values and actuators.

- Interfaces with PC over USB and LCD over UART.

- Runs a customized Marlin firmware for real-time motion coordination

⚙️ Suitable Applications

- 3D printers using Cartesian, CoreXY, or Delta mechanisms

- CNC milling, engraving, and cutting machines

- Laser cutters and plotters

- Pick-and-place or SMT soldering machines

- Industrial and DIY robotic arms

- Educational and experimental motion control systems